Torque testing is a way of determining how an object will react when it is being turned - during normal operation or being twisted until it deliberately fails or breaks. This rotational force can be 'dynamic' often delivered at ultra-high speed or 'static' at a much lower speed. Static torque measurement is increasingly used by manufacturers as a quality-control method to comply with industry standards. This is available at Material testing equipment supplier Wattek LLC.

Force testing is a way of determining how an object will react when it is subjected to tensile or compressive loads - either during its normal operation or when being pulled/pushed until it deliberately fails or breaks. These forces can be classified as tension, compression, flexure, shear and fracture. When delivered suddenly at ultra-high speed this is known broadly as 'dynamic' loading. It is typically used for cyclic-fatigue or creep testing to determine the life-cycle of materials or components.

• Abrasive Cutting Machine is the first step of preparation for Metallographic studies. Proper sectioning is required to minimize damage, which may in turn alter the microstructure of the component. • Proper cutting requires optimum selection of Cutting Wheel with appropriate size as well as proper cutting speed, load and coolant. Silent operation is realized by the tough machine body. Simple design with handle ability. Many kinds of sample fixing jig can be used on the stage.

• MOUNTING machine is includes compression mounting compounds, acrylic systems, epoxy systems, release agents & mounting accessories. Mounting your specimen is important for ease of handing and preservation of the sample edge. When deciding on which mounting technique to use, consider the size and geometry of your part, the part's susceptibility to heat and pressure, and the desired throughput specimen mounting has other benefits such as CPU Control Full-Automatic Hydraulic System.• Space-saving desk type, Light weight compact body. The running time is greatly shortened by quick heating and quick cooling. Fully-automatic one cycle (pressurizing, heating and cooling) operation. Wattek is the perfect lab equipment suppliers in dubai to get one at.

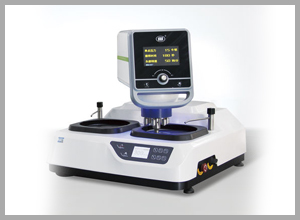

Polishing is the most important step in the preparation of a specimen for micro structural analysis. It involves removal of the previous damages that had affected the surface of the specimen to be viewed. Future tech has a very wide range of Polishing Machines from Individual pressure or Central pressure can be selected. Large LCD touch panel is easy to see and it has various user friendly functions. Semi Auto and Auto polishing Machines helps the human errors involved. Sample holder can be quickly and easily washed by simply sliding the head to the washing tube.